MACHINE

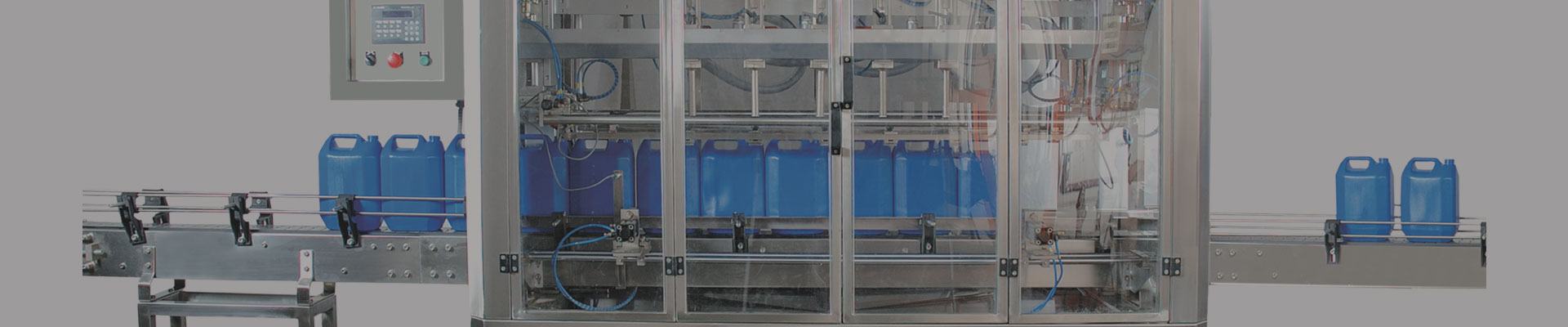

Monoblock Rotary Doser Capper Machine

We have attained wide reputation in the market by developing best quality Monoblock Rotary Doser Capper Machine

Request A QuoteTechnical Specification

Monoblock Rotary Doser – Capper

- Applications:- Oils, Cosmetics, Sauce, Ketchup, Pesticides

- Filling range : 200ml to 1000ml in the same machine.(can be customised based on requirement)

- Versatile : Automatic volume setting. No manual setting for volumne while changing pack sizes.

- Nozzle type : Rotary valve for Drip – less Filling. Dosing With Specially designed pistons.

- Volume setting : Wide HMI Panel for better interface.

- No Bottle to fill : Non contact sensors to facilitate “No container no fill” as standaed features”.

- Applications : For viscous & free flowing liquids.

- Filling principle : Volumetric : positive displacement of the products with piston & cylinder arrangement.

- Safety interlocks : Safety features enabled.

- Accuracy of filling : Repeat accuracy of +/- 0.5%

- Capping application : Suitable for screw caps / snap on capping.

- Lubricant : Automatic lubricating assembly for continous lubrication.

- Servo tempreture compensation : Auto temperature compensation for volume adjustment with changing temperature available as optional features.

Video